We have listed some of the most common error codes for Samsung ACs:

Here is the updated table with the information about the additional error codes you provided:

| Error code | Description | Possible Causes and Solutions |

|---|---|---|

| E101, E102 | Communication Error (Interior Exterior) | – Check the communication cable connections. |

| – Make sure there is no electromagnetic interference nearby. | ||

| – Check the condition of the cables and replace them if necessary. | ||

| E121 | Room Temperature Sensor Error | – Check sensor location and replace if necessary. |

| E122 | Internal Pipe Temperature Sensor Error | – Inspect and replace temperature sensors in the internal piping. |

| E154 | Fan Error (Indoor) | – Check the status of the fan and its connection. |

| – Replace the fan if necessary. | ||

| E162 | EEPROM error (Indoor) | – Consult a technician to replace or reprogram the EEPROM. |

| E163 | Option Error | – Check the system configuration and make corrections according to the user manual. |

| E203 | Communication Time Out (Main Micom and Investor Micom) | – Check connections and replace faulty components if necessary. |

| E221 | Outdoor Temperature Sensor Error (OUT-TH – Outdoor Temperature) | – Check connections and replace sensor if necessary. |

| E231 | Condenser Temperature Sensor Error (CON-TH – Cond Temperature) | – Inspect and replace the affected sensor. |

| E251 | Discharge Temperature Sensor Error (DIS-TH – Discharge Temperature) | – Check connections and replace sensor if necessary. |

| E416 | Discharge Temperature Sensor Overheating | – Check air circulation and make sure the system is working properly. |

| E422 | EEV or Valve Closing Error – Self-Diagnosis | – Inspect the valve and its connections. Replace valve if necessary. |

| E440 | Prohibited Condition Error (Heating) | – Check the configuration and operating conditions in heating mode. Adjust as necessary. |

| E441 | Prohibited Condition Error (Cooling) | – Check the configuration and operating conditions in cooling mode. Adjust as necessary. |

| E458 | Fan Error (Outdoor) | – Check the status of the fan in the outdoor unit and its connection. |

| E461 | Compressor Start Error | – Check compressor starting system and make necessary repairs. |

| E462 | AC Input Current Limit Error | – Check the AC input current limit and make adjustments as necessary. |

| E464 | IPM Overcurrent Error (OC) | – Inspect the IPM power module and replace if necessary. |

| E465 | Compressor Voltage/Current Limit Error | – Check compressor voltage/current limit and make adjustments if necessary. |

| E466 | DC-Link Low/High Voltage Error | – Check the DC-Link voltage and make adjustments as necessary. |

| E467 | Compressor Cable Missing Error | – Check compressor cable connections and repair if necessary. |

| E468 | Current Sensor Error | – Inspect current sensor and replace if necessary. |

| E469 | DC-Link Voltage Sensor Error | – Check DC-Link voltage sensor and replace if necessary. |

| E470 | EEPROM Data Error (no data) | – Check the presence of data in the EEPROM and replace if necessary. |

| E471 | EEPROM Data Error (Main Micom and Micom Inverter) | – Check the data in the EEPROM of the main Micom and Micom inverter. Replace the EEPROM if necessary. |

| E474 | Heat Sink Sensor Error | – Inspect the heat sink sensor and replace if necessary. |

| E483 | Overvoltage Protection Error | – Check voltage conditions and make adjustments as necessary. |

| E484 | PFC Overload Error | – Review the PFC loading conditions and make adjustments if necessary. |

| E485 | Input Current Sensor Error | – Inspect the input current sensor and replace if necessary. |

| E488 | AC Input Voltage Sensor Error | – Check the AC input voltage sensor and replace if necessary. |

| E500 | Heat Sink Overheating Error | – Check airflow to the heat sink and make adjustments as necessary. |

| E554 | Gas Leak Error | – Inspect the system for refrigerant gas leaks and repair as necessary. |

| Error code | Meaning | probable cause | Troubleshooting |

| CL | Auto Clean Indicator | Indoor unit that produces odors | Run the “Auto-Clean” command to remove the odor. |

| CF | Filter Clean/Reset Reminder | Dirty filter | Clean/replace dirty filter on your indoor unit |

| D.F. | Automatic defrosting | The air conditioning is defrosting | Wait for the automatic defrost to finish. |

| E3 | Indoor fan motor malfunction | Defective indoor fan or circuit board | Replace the indoor fan or circuit board, depending on which is defective |

| E4 | Forced defrosting | Low coolant level, faulty pump, broken temperature sensor or pressure fluctuation | Contact the nearest Samsung service center |

| E5 | Indoor heat exchanger sensor open/short | Defective outdoor heat exchanger sensor | Replace the indoor heat exchanger sensor |

| E6 | Outdoor heat exchanger sensor open/short | Defective outdoor heat exchanger sensor | Replace heater temperature sensor |

| E7 | Heater temperature sensor open/short circuit | Defective heater temperature sensor | Replace heater temperature sensor |

| C2 | Inner pipe sensor failure | Defective inner pipe sensor | Replace the inner pipe sensor |

| E101 | Communication failed (indoor unit) | Faulty power cables or connections around the indoor unit | Check for loose connections or power cables and fix them. |

| E102 | Communication failed (outdoor unit) | Faulty power cables or connections around the outdoor unit | Check for loose connections or power cables and fix them. |

| HE | Electric heater overheated | Power Overload | Replace Heater Temperature Sensor or PCB |

| E201 | Communication failed (between indoor and outdoor units) | Loose connections or defective PCB (printed circuit board) | Check for loose connections outdoors and indoors and if not, replace the main PCB |

| E1/21 | Room temperature sensor failure | Faulty room temperature sensor | Contact the nearest Samsung service center |

| E1/22 | Heat exchange temperature sensor failure | Malfunctioning heat exchanger temperature sensor | Contact the nearest Samsung service center |

| E1/54 | Faulty condenser or fan motor | – | Replace the condenser or fan motor. |

| E1/63 | defective EEPROM | – | Replace the EEPROM |

Error codes for Multi System AC Samsung:

Here is the updated table with the information on error codes for Multi System AC in indoor units and verification methods:

| Error code | Description | Possible Causes and Solutions |

|---|---|---|

| E1-01 | Communication Error (inability to receive data) | – Check the connection of the communication cable. |

| – Check the cable connection in other indoor units or indoor PCB. | ||

| E1-02 | Communication Error (outdoor unit cannot communicate) | – Check the cable connection on another indoor unit or on the indoor PCB. |

| E1-21 | Room Temperature Sensor Error | – Check the room temperature sensor and connection on the indoor PCB. |

| E1-22 | Heat Exchanger Temperature Sensor Error (inside) | – Check the heat exchanger sensor inside and the connection on the inside PCB. |

| E1-23 | Heat Exchanger Temperature Sensor Error (outside inside) | – Check the heat exchanger sensor outside the interior and the connection on the interior PCB. |

| E1-28 | Heat Exchanger Temperature Sensor (inside) detached error | – Check the heat exchanger sensor inside. |

| E1-29 | Heat Exchanger Temperature Sensor (outside inside) detached error | – Check the heat exchanger sensor outside the interior. |

| E1-30 | Heat Exchanger Temperature Sensor (inside and outside) detached error | – Check the heat exchanger sensors inside and outside the inside. |

| E1-54 | Fan Motor Malfunction (inside) | – Check the fan motor and wiring in the indoor unit. |

| E1-61 | More than 2 indoor units in cooling and heating mode simultaneously | – Check the operation mode of other indoor units. |

| E1-62 | EEPROM error (inside) | – Consult a technician to replace or reprogram the EEPROM in the indoor unit. |

| E1-63 | Option code configuration error | – Check and adjust the option code as necessary. |

| E1-85 | Incorrect wiring | – Check the cable connections between the indoor and outdoor unit. |

| E2-01 | Incorrect number of paired indoor units | – Check the cable connections between another indoor unit and the outdoor unit. |

| E2-51 | Compressor Discharge Sensor Error (Short/Open Circuit) | – Check the compressor discharge sensor on the outdoor unit. |

| E5-59 | Outdoor unit error | – Consult a technician for diagnosis and repair of the outdoor unit. |

Error codes for VRF Samsung:

Here is the updated table with information on error codes for VRF (DVM S) in indoor units and related communication and configuration aspects:

| Error code | Description | Possible Causes and Solutions |

|---|---|---|

| E-101 | Communication Error in the Indoor Unit | – Check the connection of the indoor unit and make sure it receives data from the outdoor unit. |

| E-102 | Communication Error between Indoor and Outdoor Unit | – Check the communication between the indoor and outdoor unit. This code is displayed on the indoor unit. |

| E-108 | Error due to repeated address setting | – Check and adjust the address settings as necessary. |

| E-121 | Interior Temperature Sensor Error | – Check the indoor temperature sensor and connection on the indoor unit. |

| E-122 | Indoor Unit EVA IN Sensor Error | – Check the EVA IN sensor of the indoor unit and the connection. |

| E-123 | Indoor Unit EVA OUT Sensor Error | – Check the EVA OUT sensor of the indoor unit and the connection. |

| E-128 | The EVA IN temperature sensor of the indoor unit has detached from the EVA IN tube | – Check the EVA IN temperature sensor and reattach it to the EVA IN tube. |

| E-129 | The EVA OUT temperature sensor of the indoor unit has detached from the EVA OUT tube | – Check the EVA OUT temperature sensor and reattach it to the EVA OUT tube. |

| E-130 | Indoor unit heat exchanger inlet/outlet sensors are detached | – Check the heat exchanger inlet/outlet sensors and reseat them. |

| E-135 | Indoor unit cleaning fan RPM feedback error | – Check the operation of the cleaning fan and its connection. |

| E-149 | Error due to indoor unit AHU master sensor setting | – Check and adjust the AHU master sensor settings as necessary. |

| E-151 | Error due to open EEV of indoor unit (detection 2) | – Check the condition of the EEV valve and repair if necessary. |

| E-152 | Error due to closed EEV of indoor unit (detection 2) | – Check the condition of the EEV valve and repair if necessary. |

| E-153 | Indoor unit float switch error (detection 2) | – Check the float switch and its connection, repair if necessary. |

| E-154 | Indoor unit RPM feedback error | – Check the operation of the indoor unit fan and its connection. |

| E-161 | Indoor unit mixed operation mode error; when the outdoor unit is preparing to operate in cooling | – Check the operation mode of the outdoor unit and make adjustments if necessary. |

| E-162 | MICOM EEPROM error on indoor unit | – Consult a technician to replace or reprogram the EEPROM in the indoor unit. |

| E-163 | Indoor unit remote control option is incorrect or absent | – Check the remote control option settings and correct them as necessary. |

| E-180 | Simultaneous opening of cooling and heating MCU solenoid (detection 1) | – Check the MCU solenoid and its connections. |

| E-181 | Simultaneous opening of cooling and heating MCU solenoid (detection 2) | – Check the MCU solenoid and its connections. |

Flashing lights on Samsung air conditioners:

Here is the updated table with information about the flashing lights on Samsung air conditioners and their meanings:

| Light Sequence | Description | Possible Causes and Solutions |

|---|---|---|

| Off – Flashing – Off | Room Temperature Sensor Error (open/short circuit) | – Check the room temperature sensor and its connection. |

| Flash – Flash – Off | Heat Exchanger Temperature Sensor Error (open/short circuit) | – Check the heat exchanger sensor and its connection. |

| Off – Off – Flashing | Fan Motor Malfunction (indoor) | – Check the fan motor and its connection. |

| Blink – Blink – Blink | EEPROM error | – Consult a technician to replace or reprogram the EEPROM. |

| Blink – Blink – Blink | Option Error | – Check option settings and make necessary corrections. |

| Off – Flashing – Flashing | Abnormal Communication Error (Interior – Exterior) | – Check the connections between the indoor and outdoor unit. |

| Flashing – Off – Flashing | Outdoor Unit Temperature Sensor Error (Outdoor Temperature Sensor, Defrost Temperature Sensor, OLP Temperature Sensor, Discharge Temperature Sensor, Heat Sink Temperature Sensor) | – Check the outside temperature sensors and their connections. |

Regarding the display of the outdoor unit board error mode:

| Lights (Yellow-Green-Red) | Description | Possible Causes and Solutions |

|---|---|---|

| Off – Off – Off | Off / VDD NG (No Power / VDD Not Good) | – Check if there is power and adjust the power supply. |

| Off – Off – Flashing | Compressor Peak Current (OC) | – Check compressor power and make necessary repairs. |

| Off – Off – On | NG Communication (No Communication) | – Check communication connections and correct problems. |

| Off – Flashing – Off | Compressor Start Error | – Check the compressor starting system and make any necessary repairs. |

| Off – Flashing – Flashing | Heat Sink Sensor Error | – Check the heat sink sensor and make necessary repairs. |

| Off – Flashing – On | Normal Operation | – The unit is operating normally. |

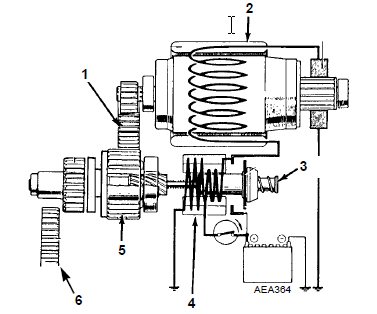

Thermo King Fuel Solenoid

Thermo King Fuel Solenoid Starter Motor – Thermo King

Starter Motor – Thermo King