The Thermo King alarm 10 indicates that the unit has detected high discharge pressure. Discharge pressure is the pressure of the refrigerant as it exits the compressor.

Possible causes of alarm code 10 include:

- Restriction in the discharge line.

- Defective or clogged expansion valve.

- Issues with condenser cleaning or fan failure, causing low airflow.

- Overcharged refrigerant.

The alarm 10 thermo king can be described in the following table:

| Alarma 10 thermo king | |

|---|---|

| Rojo | Take immediate action. High compressor discharge (or temperature). |

| If the unit shuts down, repair immediately. Otherwise, report the alarm at the end of the day. |

Fault Code Thermoking 10:

This alarm is related to a higher-than-normal discharge pressure value.

- If the fan is belt-driven, check its condition and tension.

- Inspect the local gearbox for stuck or worn bearings.

- If the condenser fan is electric, verify its voltage supply and motor behavior.

- Check if the 12-volt battery is defective. A typical sign of a worn-out battery is if the unit loses power even before activating the starter motor.

- Verify if there’s a defective High-Pressure Cutout (HPCO) switch.

- The HPCO is located on the top of the compressor.

- If the unit still doesn’t start, check the voltage of the HPCO switch.

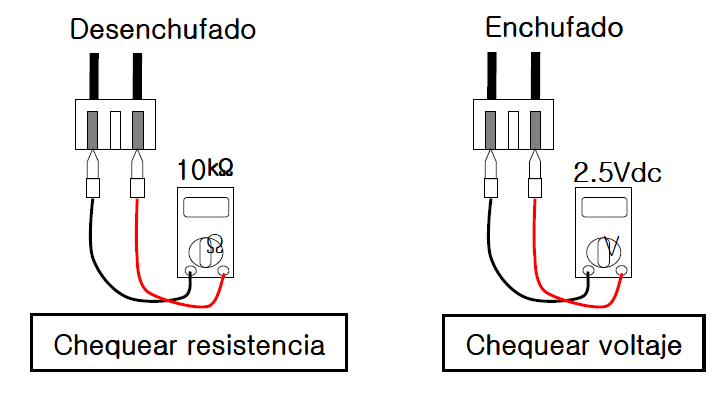

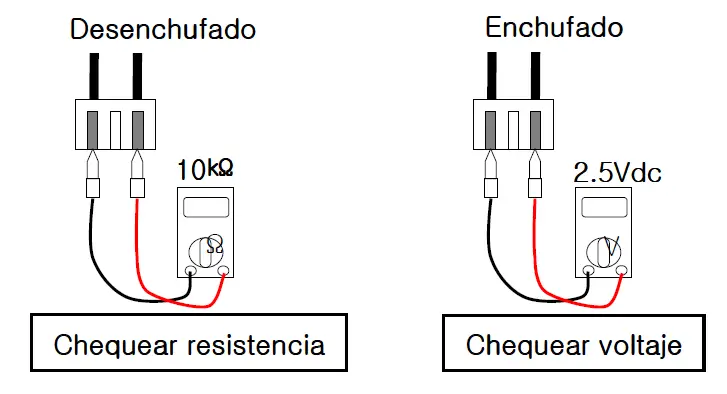

- Perform a voltage drop test to check for an open circuit.

- Trace the wiring circuit and check the fuses or switches connected to the circuit.

What to do with Thermo King Alarm 10:

In the following video prepared by conforempresarial, recommendations related to alarm 10 thermo king are shown:

- Operate the unit in Cooling mode and check the readings of the discharge and suction pressure gauges.

- When the system has a vapor injection system for compressor cooling, operate the vapor injection valve to determine if the valve activates.

- Check the resistance of the compressor discharge sensor. The resistance in many Thermoking models should be approximately 86 kilohms at 25 ºC (77 ºF). However, check the sensor type of your equipment.

- Verify the temperature of the discharge line with a separate digital thermometer and compare it with the High-Pressure Temperature value displayed in the menu.

- The unit will operate normally without the compressor sensor. However, the compressor’s high-temperature protection from the controller is not active.

High-Pressure Cutout Switch (Alarm 17):

- The high-pressure cutout switch (2) is located on the discharge service manifold of the compressor.

- If the discharge pressure increases too much, the switch opens the circuit to ground of the compressor contactor.

- The compressor stops immediately.

- The evaporator and condenser fans continue to operate normally.

- The controller determines that a high-pressure cutout switch or internal protector has activated.

- Check the condenser fan operation.